This post may contain affiliate links. If you make a purchase through these links, we may earn a commission at no additional cost to you.

When you think about 3D printing, maybe you picture plastic Yoda figures or intricate, non-functional models. It’s true, 3D printers are fantastic for creating fun objects and artistic pieces. But the real power of desktop additive manufacturing—that’s the technical term for building objects layer by layer, which is what most home 3D printers do—lies in its ability to produce practical, problem-solving items for everyday use.

Forget the novelty prints for a moment. This technology lets you design and manufacture custom parts, organizers, tools, and gadgets right in your home or workshop. It’s like having a miniature factory that can make exactly what you need, precisely when you need it. This article will explore over 15 incredibly useful things you can 3D print that can genuinely improve your daily life, helping you get organized, fix things, and make tasks easier. We’ll dive into why these prints are so handy, what materials work best for them, and how you can get started making them yourself.

Why Functional 3D Printing Matters

Moving beyond decorative items unlocks the true potential of your 3D printer. Printing functional objects isn’t just a cool hobby; it’s a practical skill that can save you time and money. Think about all those small annoyances around the house—a missing knob, tangled cables, a tool that needs a specific holder. Often, a quick trip to the store isn’t enough because you can’t find the exact part or solution you need.

This is where functional 3D printing shines. You can design or download a model that perfectly fits your specific situation. Need a custom bracket to mount something in a tricky spot? Print it. Lost the battery cover for an old remote? Print a new one. This level of customization is virtually impossible with traditional manufacturing methods for individual users.

Beyond simple replacements, functional prints allow for optimization and organization. You can create drawer dividers tailored to your exact items, tool holders designed for your specific tools and workspace layout, or cable management clips that fit your desk perfectly. This personalization leads to more efficient and less cluttered spaces.

Another significant advantage is cost-effectiveness, especially for prototypes or replacement parts. While a 3D printer and filament require an initial investment, printing a small replacement part is often much cheaper than buying a whole new product or searching for a discontinued component. It also encourages a repair-and-reuse mindset rather than simply replacing broken items.

Finally, designing and printing functional objects is a fantastic way to develop problem-solving skills. You learn to look at everyday challenges and think about how a custom-designed object could provide a solution. It combines creativity with practical engineering principles, making it a rewarding process.

Choosing the Right Filament for Functional Prints

The material you choose is crucial when printing objects meant to be used regularly or withstand stress. Different filaments have varying properties like strength, flexibility, temperature resistance, and durability. Selecting the right one ensures your print performs as expected and doesn’t break immediately.

Let’s look at some common filament types and their best uses for functional prints.

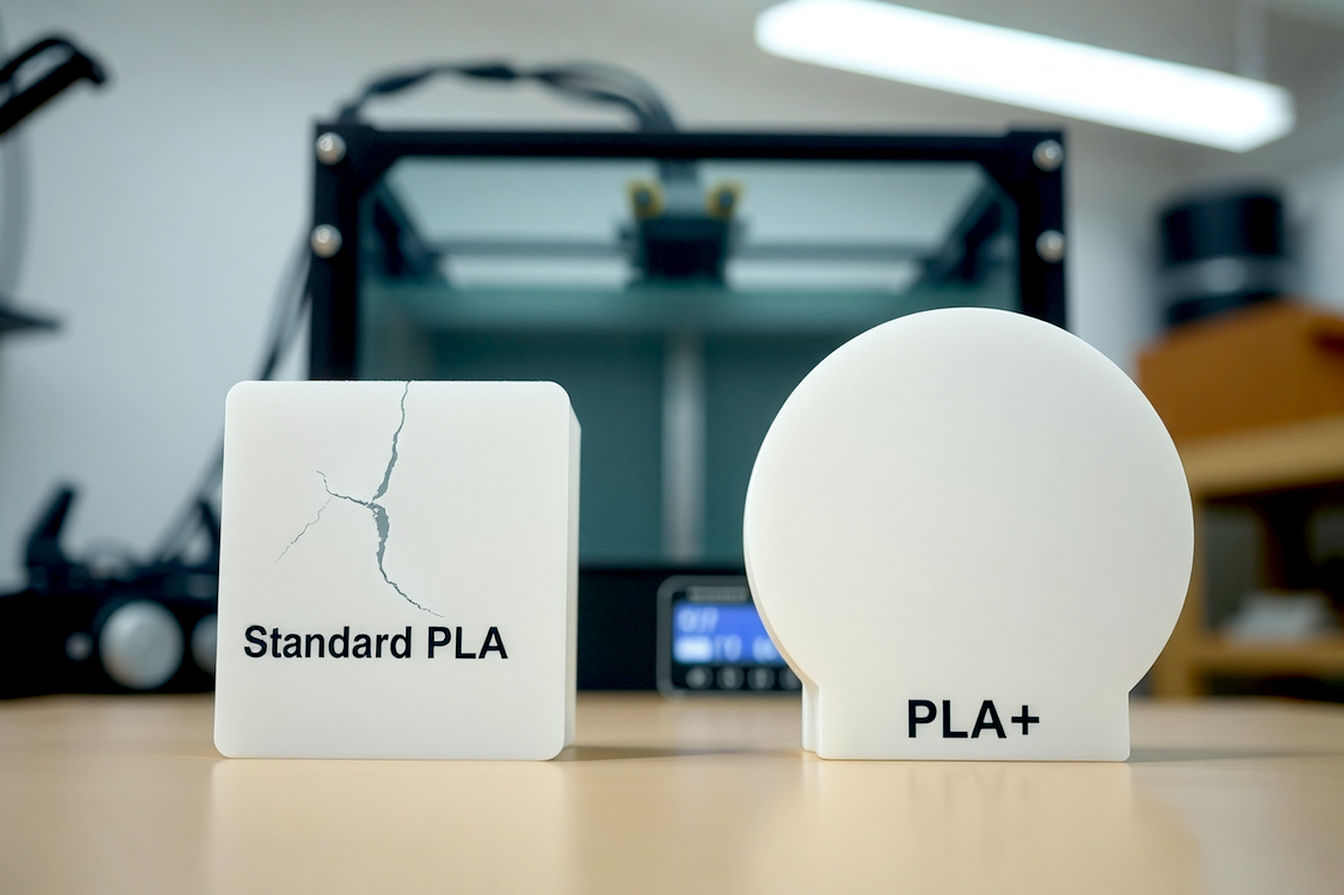

PLA (Polylactic Acid)

PLA is arguably the most popular filament for desktop 3D printing, especially for beginners. It’s made from renewable resources like corn starch or sugarcane, making it more environmentally friendly than some other plastics.

- Simple Explanation: PLA is easy to print, doesn’t smell bad, and works for lots of basic stuff. It’s good for things that don’t get hot or need to bend a lot.

- Technical Explanation: Polylactic Acid is a thermoplastic polymer with a relatively low melting point (around 180-230°C). It requires a lower print temperature and doesn’t necessarily need a heated print bed, though one helps with adhesion. PLA is quite rigid but can be brittle under stress, meaning it might snap rather than bend. It has poor heat resistance, deforming at temperatures above 50-60°C. It’s suitable for low-stress, non-heated applications like organizers, display stands, and models where precise dimensions are important but high strength isn’t critical.

PETG (Polyethylene Terephthalate Glycol)

PETG is becoming increasingly popular as a step up from PLA. It offers a good balance of properties, combining some of the ease of printing of PLA with the strength and durability of ABS.

- Simple Explanation: PETG is tougher than PLA, can handle a bit more heat, and is good for parts that need to be strong but still relatively easy to print.

- Technical Explanation: PETG is a modified version of Polyethylene Terephthalate (the plastic used in water bottles) with Glycol added to make it easier to 3D print. It prints at higher temperatures than PLA (around 220-250°C) and benefits greatly from a heated bed (70-80°C). PETG is known for its good layer adhesion, resulting in strong parts. It’s more flexible and less brittle than PLA, offers better temperature resistance (up to 70-80°C), and has good chemical resistance. This makes it excellent for functional parts requiring moderate strength, durability, and temperature resistance, such as mechanical parts, protective covers, and containers.

ABS (Acrylonitrile Butadiene Styrene)

ABS is a strong and durable plastic, familiar from things like LEGO bricks. It was one of the first plastics used in desktop 3D printing but is less common now due to printing challenges.

- Simple Explanation: ABS is really tough and can handle higher temperatures than PLA or PETG. But it’s harder to print because it can warp, and it smells bad, so you need good ventilation.

- Technical Explanation: Acrylonitrile Butadiene Styrene is a thermoplastic polymer known for its toughness, impact resistance, and higher glass transition temperature (around 105°C). It requires higher print temperatures (230-260°C) and a heated bed (90-110°C) is essential to prevent warping (a common issue called ” Absent-minded Bed Shrinkage” or just warping, caused by uneven cooling). ABS also releases potentially harmful fumes, so printing in a well-ventilated area or enclosed printer is necessary. It’s best for parts needing high strength, heat resistance, and durability, like tool handles, automotive parts (non-critical), and enclosures for electronics that might get warm.

Nylon (Polyamide)

Nylon is a group of synthetic polymers known for their exceptional strength, flexibility, and wear resistance.

- Simple Explanation: Nylon is super strong and flexible, great for parts that move or rub against other things without breaking. It’s a bit tricky to print because it absorbs moisture.

- Technical Explanation: Polyamides like Nylon 6 or Nylon 12 are semi-crystalline polymers with high tensile strength, excellent abrasion resistance, and good fatigue resistance. They can withstand significant mechanical stress and repeated use. Nylon is also somewhat flexible, allowing for snap-fit parts or living hinges. However, Nylon is highly hygroscopic, meaning it readily absorbs moisture from the air, which can ruin prints. It requires proper drying before printing and storage in a dry environment. Printing temperatures are high (240-260°C or more), and a heated bed is needed. It’s ideal for gears, bearings, structural components, and parts requiring high durability and flexibility.

TPU (Thermoplastic Polyurethane)

TPU is a type of thermoplastic elastomer, meaning it’s a plastic with rubber-like properties.

- Simple Explanation: TPU is flexible and stretchy, like rubber. It’s perfect for phone cases, feet for objects, or anything that needs to bend or absorb shock. It can be slow to print.

- Technical Explanation: Thermoplastic Polyurethane is a block copolymer offering high elasticity, abrasion resistance, and shock absorption. Its flexibility can range from semi-rigid to very soft and stretchy, depending on the specific type. TPU is often more challenging to print than rigid filaments due to its flexibility, which can cause feeding issues. Printing speeds are typically slower. It’s the go-to material for flexible parts like phone cases, gaskets, seals, vibration dampeners, and protective feet or bumpers for objects.

Choosing the right material depends entirely on the intended use of your 3D print. Consider the forces it will experience, the environment it will be in (temperature, moisture), and whether it needs to be rigid or flexible.

Useful Prints for the Kitchen

The kitchen is a prime area for functional 3D prints. Small gadgets and organizers can make cooking and storage much more efficient.

Custom Utensil Drawer Organizers

Kitchen drawers often become jumbled messes of spatulas, whisks, and spoons. Store-bought organizers are usually standard sizes that don’t quite fit your drawer or your collection of tools.

- Utility: Keep your kitchen tools neat and easy to find. Maximize drawer space by creating compartments specifically sized for your items.

- Why 3D Print: You can measure your drawer precisely and design sections for every single item you own, from the smallest tea spoon to the largest ladle. This level of tailored organization is impossible with off-the-shelf solutions. You can even design in features like angled slots for knives or specific holders for oddly shaped gadgets.

- Material Considerations: PLA is perfectly suitable for drawer organizers as they don’t experience high temperatures or significant stress. It’s easy to print and comes in many colors. Ensure the design has a solid base and walls thick enough to be sturdy.

- Technical Detail: Designing these involves taking precise internal measurements of the drawer (length, width, height) and then modeling dividers within that space using CAD software. The dividers can be simple walls or complex shapes. Printing multiple interlocking modules is often easier than printing one large piece, especially for larger drawers. Using a caliper for measurements is recommended for accuracy.

Bag Clips and Sealers

Once you open a bag of chips, cereal, or frozen vegetables, you need a way to seal it to keep the contents fresh. Small, custom clips can do the job effectively.

- Utility: Seal opened bags to prevent spoilage and spills.

- Why 3D Print: You can print clips in various sizes to fit different bags, or even design specialized clips with features like spouts for pouring. They are quick and cheap to produce compared to buying packs of clips.

- Material Considerations: PLA or PETG work well here. PETG might be slightly more durable and resistant to moisture if used for frozen food bags. The design needs a bit of flexibility to clip onto the bag, but not so much that it breaks.

- Technical Detail: Simple bag clips often use a living hinge design. A living hinge is a thin section of plastic that is designed to bend repeatedly without breaking. This is achieved by making the plastic very thin (often less than 0.5 mm) in the hinge area. The material’s flexibility (like PETG or even a slightly flexible PLA) is key here.

Egg Separator

Separating egg whites from yolks is a common task in baking and cooking. A simple tool can make this much easier.

- Utility: Easily separate the yolk from the white of an egg.

- Why 3D Print: These are simple shapes that are quick to print. You can design fun or ergonomic shapes that aren’t available commercially.

- Material Considerations: PLA is fine, but if you want it to be more durable and potentially easier to clean, PETG is a better choice as it’s less porous than PLA. Food safety is a consideration here; while many plastics are technically food-safe in their raw form, the FDM printing process can create tiny crevices where bacteria can grow. For items that touch food, it’s best to use food-safe filaments (check manufacturer specifications) and design prints that are easy to wash thoroughly. Some users apply a food-safe coating.

- Technical Detail: The design typically involves a bowl-like shape with slots or openings that allow the thinner egg white to pass through while retaining the yolk. The size and spacing of these openings are critical for effective separation.

Sink Caddy or Sponge Holder

Keeping sponges, brushes, and dish soap organized by the sink prevents clutter and allows items to dry properly.

- Utility: Organize dishwashing tools and allow sponges to drain.

- Why 3D Print: Design a caddy that perfectly fits your sink area, whether it hangs over the divider, attaches with suction cups (you’d need to buy the suction cups), or sits on the counter. You can include drainage holes exactly where needed.

- Material Considerations: PETG is ideal for this application due to its water resistance and durability in a constantly wet environment. PLA would likely degrade or become brittle over time with exposure to water and soap.

- Technical Detail: Designing involves creating a basket or tray shape with a method for attachment (hooks, flat base, slots for suction cups). Crucially, include drainage holes or slats in the base to prevent water from pooling, which can lead to bacterial growth. Consider adding small feet or a raised base if it sits on the counter to allow air circulation underneath.

Boosting Productivity: Office & Desk Prints

A cluttered desk can hinder productivity. 3D printing offers numerous ways to organize your workspace and make your tech more convenient to use.

Cable Management Clips and Organizers

Tangled cables behind your monitor or under your desk are frustrating and unsightly. Simple printed clips and channels can solve this.

- Utility: Keep charging cables, mouse cords, and power cables neat and organized.

- Why 3D Print: You can print clips designed for specific cable thicknesses or bundles. Create channels that adhere to the underside of your desk or clips that snap onto desk edges. This allows for highly customized cable routing.

- Material Considerations: PLA or PETG are suitable. PLA is easy to print for simple clips. PETG offers more durability and flexibility for clips that need to flex open and closed repeatedly.

- Technical Detail: Designs range from simple screw-in or adhesive-backed clips that hold one or two cables to more complex snap-fit channels that can route multiple wires. Some designs utilize a dovetail joint or similar interlocking mechanism to create modular cable management systems that can be expanded.

Headphone Stand

Leaving headphones lying on the desk can look messy and potentially damage them. A dedicated stand keeps them tidy and easily accessible.

- Utility: Store headphones neatly on your desk.

- Why 3D Print: Design a stand that matches your aesthetic, fits your specific headphones (especially larger or heavier ones), and potentially includes features like a hook for the cable.

- Material Considerations: PLA is usually sufficient for a basic stand. If you have very heavy headphones or want a more robust stand, PETG or even ABS would provide greater strength and stability. The base needs to be wide enough to prevent tipping.

- Technical Detail: Stands can be simple upright posts or more elaborate shapes. Consider the center of gravity of the headphones when designing the base to ensure stability. Adding a soft material like felt or a TPU print on the part that contacts the headphone band can help protect them and prevent slipping.

Pen and Tool Holders

Whether on a desk, in a workshop, or in a craft area, keeping pens, markers, or small tools organized is essential.

- Utility: Store writing instruments, small tools, or craft supplies upright and accessible.

- Why 3D Print: Create holders with compartments sized exactly for your items—thick markers, thin pens, screwdrivers, paintbrushes. Design holders that fit specific spaces, like pegboards or desk corners.

- Material Considerations: PLA is generally fine for desk use. For workshop tool holders where items might be heavier or impact is possible, PETG or ABS would be more durable.

- Technical Detail: Designs can be simple cups or complex grids of varying hole sizes. For pegboard holders, design hooks or clips that fit the standard pegboard hole size and spacing (often 1 inch center-to-center with 1/4 inch holes). Ensure wall thickness is adequate for the weight of the contents.

Monitor Stand or Riser

Raising your monitor to eye level can improve ergonomics and free up space underneath for storage.

- Utility: Elevate a computer monitor for better posture and provide storage space below.

- Why 3D Print: Design a stand to the exact height you need. Include custom compartments or drawers underneath sized for your keyboard, mouse, external hard drives, or notebooks.

- Material Considerations: This print needs to support the weight of your monitor, so strength is critical. PETG or ABS are better choices than PLA. Using a higher infill percentage (e.g., 50% or more) and thicker perimeters (outer walls) will significantly increase the print’s strength.

- Technical Detail: The design must account for the weight distribution of the monitor. Use a sturdy internal structure, like a grid or honeycomb infill pattern, for maximum strength with less material. Ensure the top surface is large enough for the monitor base and the legs or supports are robust. Adding non-slip feet (maybe printed in TPU or purchased separately) is a good idea.

Bringing Order: Organization Solutions

Clutter is a common problem, and 3D printing offers countless ways to create custom storage and organizational systems for almost anything.

Gridfinity System Bins

Gridfinity is a popular, open-source organizational system based on a modular grid. You print baseplates and bins of various sizes that snap together, allowing you to create highly customized storage arrays.

- Utility: Organize small parts, components, tools, or craft supplies in drawers, on shelves, or on workbenches.

- Why 3D Print: The entire system is designed for 3D printing. You can print bins in endless sizes and configurations to fit specific items and spaces. It’s incredibly flexible and expandable.

- Material Considerations: PLA is sufficient for most Gridfinity bins and baseplates as they are typically used for static storage. If storing heavier metal parts or using in a workshop environment, PETG might offer more durability.

- Technical Detail: The Gridfinity system uses a standard 42mm x 42mm grid unit. Bins have specific dimensions and features (like magnetic bases or label holders) that allow them to interlock with baseplates or other bins. Understanding the Gridfinity standard dimensions is key to designing compatible bins or accessories. The modularity comes from precise tolerances in the design that allow parts to snap or slide together.

Drawer Dividers

Similar to kitchen organizers, custom dividers for office, bedroom, or garage drawers can eliminate clutter.

- Utility: Separate items within a drawer, keeping contents tidy and easily accessible.

- Why 3D Print: Design dividers to fit any drawer size and create compartments tailored to specific items like socks, tools, craft supplies, or electronics components.

- Material Considerations: PLA is usually adequate for most drawer dividers. For heavy-duty use in a garage, PETG or ABS might be preferable.

- Technical Detail: Dividers can be simple interlocking pieces, walls that fit into a frame, or bins with integrated dividers. Measuring the internal dimensions of the drawer is the first step. Designing interlocking pieces often uses slots and tabs that slide together to form the grid structure. Ensure the height of the dividers is appropriate for the drawer depth.

Battery Organizers

Loose batteries rolling around in a drawer are inconvenient and make it hard to see what you have. Organizers designed for specific battery sizes solve this.

- Utility: Store batteries neatly by size (AA, AAA, 9V, etc.) and keep track of how many you have.

- Why 3D Print: Design compact organizers that hold a specific number of batteries in a small footprint. You can create versions for different battery types or even designs that dispense batteries from the bottom as you take one from the top.

- Material Considerations: PLA is perfectly suitable for battery storage as there’s no significant stress or heat involved.

- Technical Detail: Designs involve creating slots or compartments sized precisely for standard battery dimensions. For dispensing designs, a slight angle or a specific opening at the bottom allows gravity to feed the next battery. Ensure the tolerances are correct so batteries fit snugly but can still be easily removed.

Wall Mounts and Hooks

Need to hang something on the wall – a tool, a picture frame (lightweight), a roll of tape? A custom-designed mount or hook can provide a perfect fit.

- Utility: Hang items on walls, pegboards, or other surfaces.

- Why 3D Print: Design mounts specifically for the item you need to hang and the surface you’re attaching it to (e.g., a hook that fits a specific tool handle, a mount with screw holes spaced to match wall studs or pegboard).

- Material Considerations: The material choice depends heavily on the weight of the item being hung. For lightweight items, PLA might suffice. For heavier tools or objects, PETG or ABS with a high infill and sturdy design are necessary. The method of attachment (screws, adhesive, pegboard clips) also influences the required material strength.

- Technical Detail: Designing wall mounts requires considering the load path – how the weight of the object is transferred through the print to the mounting surface. Use generous fillets or rounds on internal corners to reduce stress concentrations. If using screw holes, design them slightly oversized or include a countersink for the screw head. For pegboard hooks, ensure the hook dimensions match the pegboard standard.

DIY & Repair: Tools and Home Improvement

3D printing can be incredibly useful for small repair jobs, creating custom tools, or making jigs to assist with DIY projects.

Custom Tool Holders and Jigs

Organizing tools is essential for any DIY enthusiast or professional. Custom holders keep tools accessible and protected. Jigs provide guides for cutting, drilling, or assembly.

- Utility: Store tools efficiently, create guides for precise work.

- Why 3D Print: Design holders for specific tools that don’t fit standard organizers. Create jigs tailored to a particular task, like a drilling guide for a specific pipe size or a cutting guide for an awkward angle. This task-specific customization significantly improves accuracy and efficiency.

- Material Considerations: For tool holders, PETG or ABS are generally preferred over PLA due to their durability and impact resistance, especially in a workshop environment where tools might be heavy or dropped. For jigs that need to withstand friction or contact with cutting tools, Nylon or even composite filaments (like carbon fiber reinforced PETG or Nylon) might be necessary for wear resistance and rigidity.

- Technical Detail: Designing tool holders involves accurately measuring the tool’s dimensions and creating a snug fit. Jigs require precise angles and measurements to ensure accuracy in the task they guide. Consider how the print will be secured during use (clamps, screws). Using threaded inserts (small metal nuts that can be heat-set into plastic) can create strong, reusable screw points in your printed jigs or holders.

Replacement Knobs, Handles, and Covers

One of the most common and satisfying uses of functional 3D printing is replacing broken or missing parts on appliances, furniture, or electronics.

- Utility: Replace damaged or lost parts like knobs, handles, battery covers, or small clips.

- Why 3D Print: Often, finding an exact replacement part for an older item is difficult or expensive. 3D printing allows you to reverse-engineer the broken part (measure it and design a new one) or design a functional alternative. This can save you from having to replace an entire item just because of a small broken piece.

- Material Considerations: The material depends on the original part’s function and environment. A stove knob needs high heat resistance (ABS or ASA). A drawer pull can likely be PLA or PETG. A flexible battery cover might need TPU or a thin, flexible design in PETG.

- Technical Detail: This often involves careful measurement of the broken part and the item it fits onto. Digital calipers are invaluable here. You need to accurately model the attachment mechanism (e.g., a D-shaped shaft for a knob, screw holes for a handle). Getting the tolerances right is crucial so the new part fits snugly but isn’t too tight. You might need to print several iterations to get the fit perfect.

Simple Brackets and Mounts

Need to mount a small sensor, secure a pipe, or create a standoff for a circuit board? Simple brackets are quick to design and print.

- Utility: Secure objects, create mounting points, provide structural support.

- Why 3D Print: Design a bracket with the exact dimensions, angles, and mounting holes needed for a specific application. This is far faster and cheaper than fabricating a metal bracket for a one-off need.

- Material Considerations: PLA is okay for light loads in stable environments. PETG or ABS are better for more demanding applications where strength or temperature resistance is needed. Consider the direction of the load relative to the print layers; prints are typically strongest in the X-Y plane (flat on the build plate).

- Technical Detail: Designing brackets involves understanding the forces the bracket will need to withstand. Use appropriate wall thicknesses and consider adding ribs or gussets (triangular supports) to increase rigidity without adding excessive material. If using screws, ensure the holes are modeled correctly for the screw size and type.

Personalizing Your Life: Accessories & More

Beyond the home and workshop, 3D printing can create unique and functional items for personal use, travel, or specific hobbies.

Custom Phone Cases and Grips

While many phone cases are available commercially, 3D printing allows for unique designs, custom fits, or integrated features.

- Utility: Protect your phone, improve grip, add personalized style.

- Why 3D Print: Design a case with specific textures, patterns, or cutouts. Create ergonomic grips tailored to your hand. Add features like a built-in stand or a loop for a strap.

- Material Considerations: TPU is the ideal material for protective phone cases due to its flexibility and shock absorption. For rigid cases or grips that attach to a standard case, PLA or PETG can work.

- Technical Detail: Designing a phone case requires accurate measurements of the phone model, including button placement, port locations, and camera bumps. Creating a case with a good fit involves understanding snap-fit design principles and using appropriate tolerances so the case snaps securely onto the phone but can still be removed. Flexible TPU cases require careful slicing settings, including slower print speeds and optimized retraction to prevent stringing.

Keychains with Specific Functions

A keychain doesn’t just have to hold keys; it can incorporate small tools or features.

- Utility: Hold keys, provide a small tool (e.g., bottle opener, shopping cart coin), add personalization.

- Why 3D Print: Design a keychain with a specific shape, text, or logo. Integrate a small, simple tool that you frequently need on the go.

- Material Considerations: PLA or PETG are suitable. PETG might be more durable for items that get a lot of wear and tear in a pocket or bag.

- Technical Detail: Designs can be simple flat shapes or more complex objects. If integrating a tool, ensure the design is robust enough for the intended use. For instance, a bottle opener needs sufficient thickness and strength at the leverage point. Consider adding a reinforced loop for the keyring itself, as this is a common failure point.

Wallet Inserts or Card Holders

Create custom inserts for your wallet or standalone cardholders for specific purposes.

- Utility: Organize cards, hold a small key or coin, create a slim wallet alternative.

- Why 3D Print: Design an insert that fits your wallet perfectly and holds cards or other small items exactly how you want. Create a minimalist cardholder for carrying just a few essential cards.

- Material Considerations: PLA is generally fine for items kept inside a wallet. PETG might offer more durability for a standalone cardholder that is frequently handled.

- Technical Detail: Designing cardholders involves creating slots or compartments sized precisely for standard credit card dimensions. The thickness of the print is important for keeping the overall profile slim. For wallet inserts, measure the internal dimensions of the wallet’s card slots or pockets to ensure a proper fit.

Small Custom Enclosures

Need a project box for electronics, a case for an SD card, or a dispenser for small items?

- Utility: House electronics, store small components, dispense items.

- Why 3D Print: Design an enclosure with the exact dimensions, cutouts for ports or buttons, mounting points for circuit boards, or internal dividers needed for a specific project or item.

- Material Considerations: PLA is suitable for basic storage or non-electronic enclosures. PETG or ABS are better for electronics enclosures, especially if heat dissipation is a concern or if the enclosure needs to be more robust. Consider using materials with specific properties like ESD-safe filaments for sensitive electronics.

- Technical Detail: Designing enclosures requires precise measurements of the components being housed. Include features like standoffs for mounting circuit boards, cutouts for connectors, and perhaps a lid that snaps or screws on. Using heat-set inserts can create durable screw threads in plastic posts for securing lids or mounting components. Design ventilation if the electronics generate heat.

Getting Started with Functional Prints

Ready to start printing useful things? Here’s how to begin:

Find Existing Models

The easiest way to start is by downloading models that others have already designed. Websites like Thingiverse, Printables, MyMiniFactory, and Cults3D host vast libraries of 3D models, many of which are functional. Search for terms like “organizer,” “tool holder,” “bracket,” “clip,” or the name of a specific item you need.

- Simple Explanation: Look online for designs that other people have already made and shared.

- Technical Explanation: These platforms host STL files (Stereolithography files) or 3MF files, which are common file formats for 3D models. You download these files and then open them in a slicing software.

Learn Basic Design Principles

While you can find many useful models online, the real power of functional printing comes from being able to design your own solutions. You don’t need to be an engineer, but understanding some basic principles helps.

- Simple Explanation: Learn how to make simple shapes and combine them using easy computer programs.

- Technical Explanation: Start with user-friendly CAD (Computer-Aided Design) software like Tinkercad (web-based, great for beginners) or Fusion 360 (more powerful, free for hobbyists). Learn basic operations like creating sketches, extruding shapes, combining/subtracting objects, and adding features like holes or fillets. Focus on designing parts with appropriate wall thicknesses, understanding how overhangs affect printing (and when supports are needed), and considering how parts will fit together (tolerances).

Master Your Slicing Software

Slicing software (like Cura, PrusaSlicer, or Simplify3D) is the bridge between the 3D model and your printer. It turns the model into layers and generates the toolpath (G-code) the printer follows.

- Simple Explanation: This program tells your printer how to build the object layer by layer. You use it to set things like how strong the inside of the print is and how thick the outside walls are.

- Technical Explanation: For functional prints, pay close attention to settings like infill density and pattern, number of perimeters (wall layers), and layer height. Higher infill (e.g., 30-60% or even higher for maximum strength) and more perimeters (e.g., 3-5 or more) significantly increase the strength and durability of a part. Choosing the right infill pattern (like grid, rectilinear, or gyroid) can also affect strength and print time. Layer height affects print time and detail; for functional parts, a slightly thicker layer height might be acceptable if strength is the priority.

Choose the Right Material (Again!)

Based on the function of your print, revisit the material section and select the filament that best suits the application. Don’t try to print a load-bearing bracket in basic PLA if you expect it to last.

Conclusion

3D printing is far more than just a way to make plastic trinkets. It’s a powerful tool for solving everyday problems, organizing your space, repairing broken items, and creating custom solutions that simply don’t exist commercially. From simple cable clips and kitchen gadgets to robust tool holders and replacement parts, the potential for useful 3D prints is enormous.

By understanding the capabilities of different materials and learning some basic design principles, you can transform your 3D printer into a versatile manufacturing device. It empowers you to move beyond consuming products and start creating practical items that genuinely enhance your daily life. So, look around your home, identify a small problem, and see if a custom 3D printed solution could be the answer. You might be surprised at just how useful your 3D printer can be.